What is our Sensor?

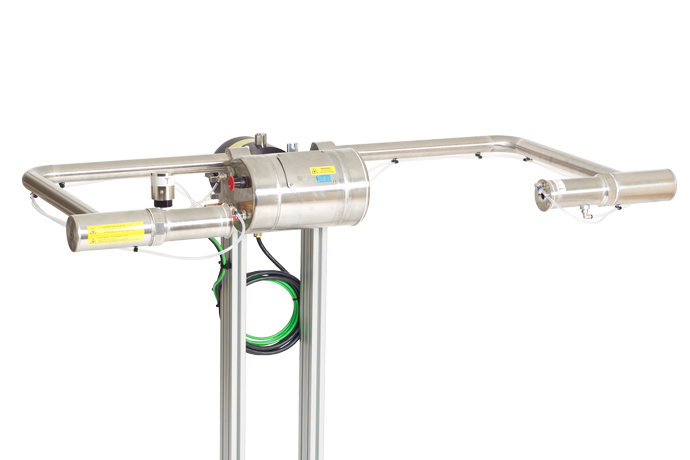

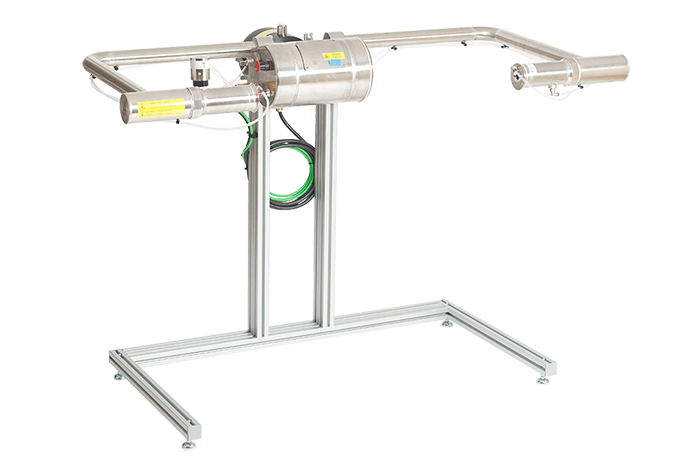

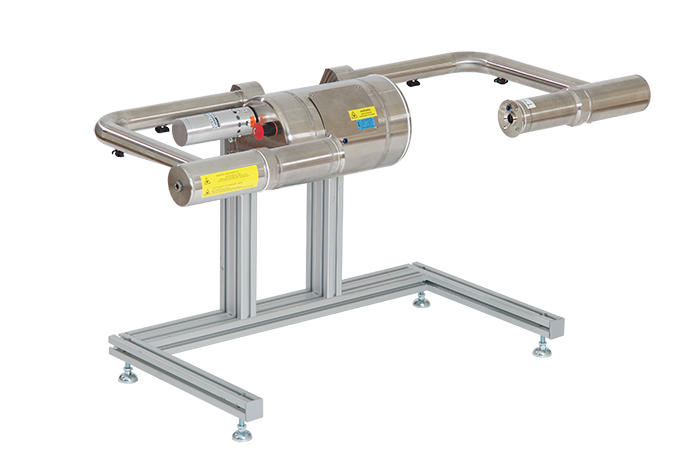

Our hardware is used to image and size droplets, particles, and bubbles and to characterize multi-phase systems. Our hardware operates in extreme and hazardous environments (including Class 1 Division 1 or Zone 1 Hazardous Locations) within many industries including automotive, coating, agriculture, pharmaceutical, food or aerospace. We designed our sensor to be compact, flexible, robust, reliable, and easy to use. This is why we included a built-in processing unit that enables our hardware to be used with any computer, tablet, or phone and can easily connect to your facilities network.